As businesses seek new productive efficiencies and competitive edges, AGVs/AMRs have exploded in popularity over the last few years. And it was almost certainly Amazon that lit the fuse in 2012. That’s when the e-commerce giant purchased Kiva Systems, an AMR manufacturer, for $775 million. The company now operates well over 100,000 robots in its warehouses.1

But as far as AGVs/AMRs have come in prevalence, they’ve come even further in affordability. In the early 2000s, even the most basic AGVs/AMRs could cost as much as $360,000.2 They were significant investments reserved only for the well-funded early adopters of the world.

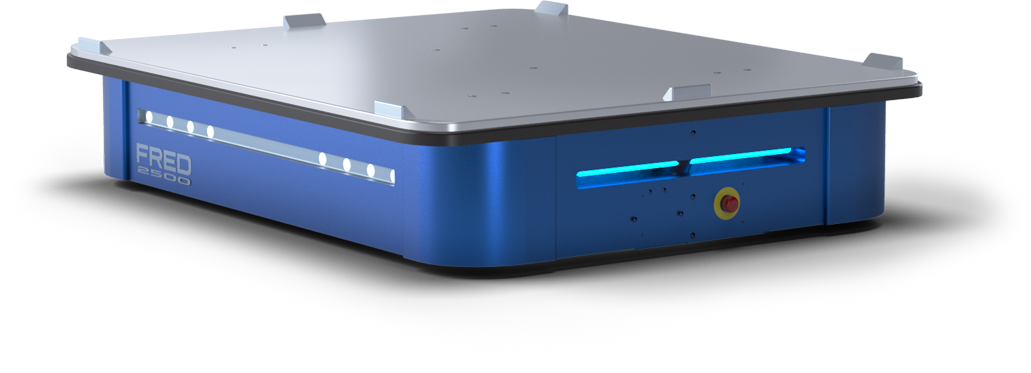

Today’s AGVs, however, can be had for far less despite being far more capable. FRED, for example, ASI’s heavy-duty AGV, costs only $35,000 to purchase. FREDDiE, its medium-duty counterpart, costs only $20,000. But getting started with either robot—and many others on the market—doesn’t require even that level of investment.

…as a Service: The Business Model Modernizing Nearly Every Industry

As impossible as it sounds, you can now get started with a new AGV for less than the cost of a new iPhone. And it’s all thanks to a relatively new business model: XaaS.

The acronym XaaS stands for “Anything as a Service.” Cloud software vendors popularized the as-a-Service business model with familiar SaaS (Software as a Service) products like Google Apps, Salesforce and Dropbox. Even Spotify and Netflix can fall under a SaaS designation. These services are so prevalent because they make the tools, resources and entertainment we need incredibly accessible—and for a considerably reduced price.

Just consider what it would cost to own every song on Spotify. Tens of millions of dollars. But thanks to SaaS, you can rent a month’s access to 50 million songs for less than the cost of a single album. And thanks to the business model behind it, we now have an acronym soup of as-a-Service solutions. And of them starts with the letter R.

RaaS

Robots as a Service (RaaS) is one of the newer XaaS models. It generally comes in two forms: cloud-service robots or rented robots. Cloud-service robots gather data as they operate and send it to the cloud for humans to later analyze. An example would be one of Google’s self-driving cars. As it drives, numerous sensors collect data about their surroundings. This data is then fed to the cloud, where it can be analyzed and used to “teach” the cars to be better drivers. It’s powerful technology. But also complex. And when applied to industrial robots—including some AGVs—expensive.

The other RaaS category for AGVs—rented robots—is far more accessible. Under this model, you’re simply renting an AGV for a designated period of time. The advantages of rented AGVs are numerous. Less upfront capital. Predictable costs. No long-term commitments. And depending on the AGV, no technical barriers to entry.

Who’s Taking Advantage of RaaS?

Nearly every industry has invested in some sort of automation. For warehouses and manufacturers, the biggest players led the charge by adopting AGVs into their logistics. To keep on par with market demands, AGVs are table stakes for these companies. Now, the same is true for companies of every size and scale worldwide.

To remain competitive, smaller businesses that operate warehouses and manufacturing facilities have found AGV investments to be crucial. But until recently, the barriers to entry were both technologically and financially prohibitive. The right RaaS model for the right AGV, however, can eliminate those barriers.

FRED and FREDDiE are two examples of AGVs that offer RaaS rental models nearly any SME can afford to get started with. ASI designed these vehicles to overcome once-overwhelming barriers for companies that sought new efficiencies and competitive edges.

FRED’s RaaS Rental Program

FRED is known for its simplicity and capability. It only takes two hours to install or reconfigure its route. It requires no software or wireless connectivity, which means no software maintenance agreements or ongoing IT. It charges automatically. And it still carries up to 2,500 pounds and tows up 5,000 pounds.

For a business that’s already experienced the benefits of an AGV like FRED, its $35,000 purchase price is an incredible bargain. In a previous article, we did that math and found that FRED easily achieves ROI in as few four months.

But you can also rent FRED under its RaaS rental program. And the program was designed to be as straightforward as FRED itself:

- $1,000 per month

- 6-month commitment

- Free shipping to your facility (you only pay for shipping if you return FRED)

- $30,000 buyout option after six months

That’s it. Warehouse automation and its myriad benefits have never been more accessible. All it takes is $1,000 to get started (or, for FREDDiE, $750).

What Do You Get for $1,000 Per Month?

The short answer is, a whole lot more than $1,000 per month in potential savings, productivity and efficiency,

Under typical circumstances, you might put FRED to work for 16 hours per day, 30 days per month. That puts FRED’s hourly cost under its RaaS model at just $2.08.

The best way to put that figure into perspective is to compare it to the most common alternative: a human operating a forklift. Based on our calculations from AGVs: Can they really achieve ROI in one year?, the average hourly cost for human + forklift combo is a little over $18.

FRED is nearly nine times less expensive for the same amount of work. But the benefits don’t end at payroll savings

- More Productivity – Employees can now be redeployed to safer, more productive tasks while FRED handles repetitive and predictable material movements. Freed-up labor for tasks that demand more skill is essentially free labor.

- More Human Safety: One or two fewer employees operating forklifts or tuggers means increased safety and decreased risk of injury and workers’ comp.

- More Product Safety: Humans are naturally prone to error, and damaged products are both costly to replace and a supply-chain interference.

- More Real Estate: Less forklift traffic frees up square footage. Real estate is a valuable asset, and having more of it available on the warehouse or factory floor opens possibilities for new production lines or projects.

- More Flexibility: Unlike a conveyor’s path, an AGV’s route can be very easy to reconfigure. Because FRED follows a simple-to-install magnetic tape path, its route can be reconfigured in about two hours.

- More Labor Availability: During times of labor shortages, there will be less need to compete for skill. Just one AGV handling material movement 16 hours per day can free up two or more employees.

- More End-of-Line Efficiency: An AGV can dramatically increase EOL process efficiency. Because FRED is automated, it can bring new capabilities to non-automated equipment like palletizers, stretch wrappers, checkweighers and more.

An AGV like FRED can help you achieve each of the benefits above whether you purchased it or rented it as part of a RaaS program. But a few more significant benefits are exclusive to RaaS rentals.

- Quickly Determine if an AGV Is Right for You: A RaaS rental program allows you to test the waters with material-movement automation at a very low cost. That’s a huge benefit if you’re new to automation or AGVs. Because a RaaS rental is temporary, you can have peace of mind while exploring automated productivity. This is a great way to determine if an AGV is right for you. And if it is, you can turn your rental into a buyout.

- Near-Instant ROI: As an upfront purchase, FRED achieves a return on your investment in as few as four months. That means it’s saving you about $290 per day. As a rental, the same math still applies. But FRED achieves ROI each month within about 4 days, over and over again.

- Massive Scalability: FRED’s purchase price is affordable for nearly any SME. But what happens if you run a small- or medium-sized operation and want more AGVs? Five AGVs for $175,000 is still a bargain. But not every balance sheet can absorb an upfront investment of that size. Most, however, can absorb a $5,000 monthly investment. And the ability to spread your capital investments in automation without taking on a loan is unique to the RaaS business model.

You may be sacrificing a bit of long-term ROI with a RaaS rental as compared to an upfront purchase. But in return, you get more flexibility and less risk should you decide an AGV isn’t right for you.

The (R)Evolution of Automation

As much as automation has evolved over the past decade, so has its accessibility. And that evolution is now being driven not only by affordable AGVs. It’s being driven by affordable AGVs made even more economical by the RaaS model.

RaaS fuels business growth in ways an upfront purchase couldn’t have years ago, primarily because it eliminates any perceived investment risk. For this reason and others mentioned previously, the RaaS market is erupting. Through 2022, analysts expect it to grow at a CAGR of nearly 20%.3 And that makes sense—RaaS almost completely eliminates financial barriers to entry. Meanwhile, AGVs like FRED eliminate technological barriers to entry.

FRED and its RaaS rental program are a potent combination that allows nearly any business to get started with automation. After placing your order, you could be up and running—and experiencing a profound growth in productivity—in a matter of hours. And all at a cost of $1,000 to get started.

RaaS may be an evolution. But in its wake, it’s leaving behind something far more powerful from which businesses of all sizes stand to benefit: the elements of an industrial revolution.

Automation Questions?

Businesses across many industries are now turning to automation technologies as powerful solutions to once unforeseeable material-movement challenges. We’re here to help you navigate the automation landscape, and drive your business forward. To learn more about how FRED and FREDDiE provide easy-to-implement solutions to complex challenges, contact an ASI Automation specialist today at info@fredagv.com.

[1] Vincent, J. (2019, January 21). Amazon warehouse workers are getting utility belts that ward off robots. Retrieved from The Verge: https://www.theverge.com/2019/1/21/18191338/amazon-robot-warehouse-tech-vest-utility-belt-safety

[2] Solomon, A., Wilck, J., & Kori, R. (2004, March 16). Introduction to Automatic Guided Vehicles. Retrieved from Grado Dept. of Industrial & Systems Engineering at Virginia Tech.

[3] Market Reports World. (2018, January 12). GLOBAL ROBOTICS AS A SERVICE (RAAS) MARKET 2018-2022.