The Automated Guided Vehicle (AGV)/Autonomous Mobile Robot (AMR) market is exploding. But it’s no longer the Amazons of the world lighting the fuse. It’s small- to medium-sized businesses. The incredible ROIs these robots deliver are impossible to ignore. And as AGV technology has grown more sophisticated, the barriers to entry for automation (i.e., the upfront costs), have plummeted. But just how low have they fallen?

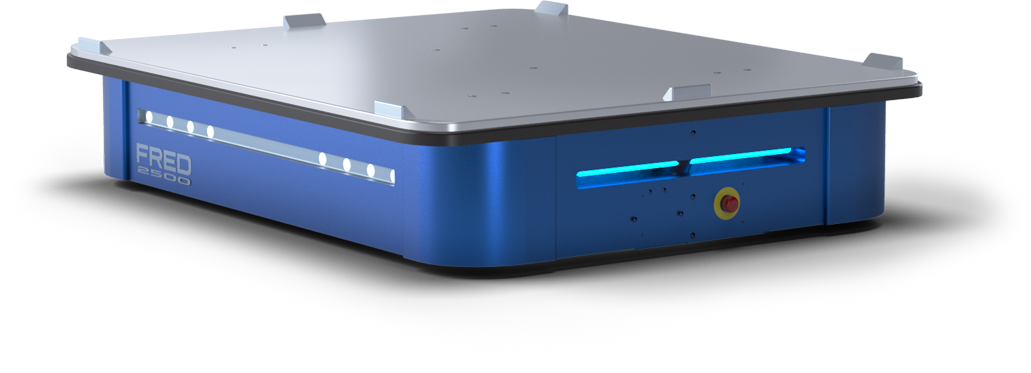

You can purchase an AGV like ASI’s own FRED or FREDDiE for just $35,000 or $20,000, respectively. And you’ll not be sacrificing any capability at those price points. FRED—the heavier-duty model of the two AGVs—carries up to 2,500 lb and tows up to 5,000 lb.

With reduced costs and increased capabilities, the gains in productivity and efficiency AGVs deliver are finally accessible to all. This accessibility has developed into a symbiotic growth relationship; as AGVs drive bottom lines, bottom lines drive the market for AGVs.

How Quickly is the Market Growing?

Quicker than estimates ever saw coming. By the end of 2015, the global AGV/AMR market was valued at just over $800 million and expected to nearly double in size within nine years. But just three years later, its valuation had already eclipsed $1.5 billion. At that time, estimates once again saw the market doubling within nine more years. And once again, the market beat estimates, achieving a valuation of $3 billion by 2019—just one year later.

Today, estimates see the global AGV/AMR market hitting a valuation of just over $8.5 billion by 2027. But clearly, AGV/AMRs are bucking estimates. If the trend we’ve witnessed over the past few years is any indication, the market will hit that valuation far sooner as more and more businesses turn to automation to drive their bottom lines.

Who’s Driving the Growth?

Not long ago, AGVs/AMRs were reserved for e-commerce giants and Fortune 500 manufacturers. In 2014, Business Insider published an article detailing Amazon’s push into automation two years after its acquisition of Kiva Systems. A cost-benefit analysis referenced in the article found these startling facts:

1. Just one AGV/AMR saves $570,000 annually on labor.

2. Each AGV/AMR saves $41,000 in capital savings annually (e.g., on the costs of forklifts and required maintenance).

3. AGVs/AMRs like those used by Amazon during their push into automation delivered an ROI of 240% and paid for themselves within 4 months.

Considering those numbers, it’s no wonder businesses around the globe became attracted to AGVs and AMRs. And now that models like FRED and FREDDiE have entered the market at a fraction of the cost of what Amazon was using, that attraction is only growing—as are the projected ROIs and cost savings.

The affordability of today’s AGVs are exactly what small- to midsize enterprises (SMEs) are taking advantage of today. These businesses—now with access to competitively priced AGVs—are expected to dominate the ever-increasing adoption of this efficient, productivity-boosting technology.

So, which industries will AGVs grow most in 2020? Now that so many SMEs now have access to AGV technology, there are too many to list in this article. But we’ll cover a few standouts.

Retail

Huge e-commerce players like Amazon catalyzed the exponential growth we’ve recently seen in the AGV/AMR market. Now, it’s retail businesses of all sizes driving the growth. If you’re in retail and operate a warehouse, you stand to benefit from automation.

What’s driving the growth? A number of factors come into play.

Increased globalization. The booming emergence of online and bulk retailing. Always-rising customer demand. Retail companies have to contend with this growing pressure—not to mention compete with each other. And they need to do it efficiently. AGVs/AMRs in warehouses and stores help them do just that.

Consider an AGV like FRED. Even working just five days per week for two eight-hour shifts each day, its cost comes to just $6.25 per hour over the course of one year. After that, FRED works for free. But the robot can actually work 24/7/365. Essentially, FRED performs over three times the amount of work a human material mover can for less than a third the cost. It’s easy to see just how quickly the right AGV not only pays for itself but also delivers an unbeatable ROI.

Current forecasts suggest that retailers will drive the highest CAGR for the AGV/AMR market over the next few years. Low-cost, high-productivity AGVs like FRED, in turn, will drive higher profits for the retailers that implement them.

Automotive

Retail may be forecasted to grow the most from AGV adoption, but the automotive industry holds the largest share of the market. Early on, only the largest auto companies recognized the need for more efficiency through automation. Now, it’s not just the major manufacturers using AGVs and AMRs for material transport. It’s their suppliers and smaller aftermarket parts manufacturers, too.

Suppliers and parts manufacturers have to continuously focus on managing their goods and stock. Small parts. Windshields. Body panels. Batteries. Even workshop equipment and reactive liquids. AGVs and AMRs streamline their every movement. Humans are prone to error, and damaged goods in the automotive industry are very costly. AGVs and AMRs eliminate human error.

AGVs and AMRs also free up floor space to improve warehouse storage capacity. And finally, an AGV or AMR can’t be unproductive. In a highly competitive automotive market with often razor-thin margins, you literally can’t afford not to have AGVs and/or AMRs working alongside your skilled labor.

Food & Beverage

The food and beverage industry is one likely to gain the most from increased AGV/AMR adoption. That growth is, in part, due to the efficiencies that retail continues to witness from automation.

As online retailing grows, so too does the ordering of food and beverage products. This new food-delivery paradigm—often direct-to-consumer—puts immense pressure on food and beverage manufacturers. They need to do more than just keep up with demand. They need to optimize their operations to do so in an efficient and timely manner.

Many food products are heavily commoditized. To stay competitive, most manufacturers must continuously seek out new ways to increase the cost-effectiveness of their operations. And that’s why food and beverage companies of all sizes are turning to AGVs and AMRs for help.

An AGV/AMR significantly reduces incidences of spilled and damaged products. It also allows small- to mid-sized companies to make better use of their workforces. Their skilled labor is freed to work in more productive capacities than material movement.

AGVs/AMRs deliver competitive advantages to any business in the food and beverage industry. But in a market that sees constant consolidation, the advantages to smaller players are significantly amplified.

Manufacturing

The manufacturing sector as a whole has long embraced AGVs and AMRs. Whether transporting raw materials or taking finished goods through an EOL (End of Line) process, the automated vehicles offer significant efficiencies humans simply can’t match. But in years past, all but the largest firms tended to shy away from AGV/AMR technology. The robots came with high upfront investments and were complex to implement and maintain.

But now, AGVs like FRED and FREDDiE are introducing the productivity-enhancing benefits of automation to manufacturers of all sizes and across even more industries. The robots hit the right price point. And because their setup is so simple, they can be fully operational within 2 hours.

This new accessibility is a huge boon to small- and medium-sized manufacturers. The benefits of AGVs and AMRs—space savings, cost reductions, worker-injury reductions, blazingly fast ROIs and more—are rippling throughout the sector. It’s expected that it will now be the smaller firms that stand to grow the most from the availability of low-cost, low-complexity, high-productivity AGV/AMR technology.

Who else?

The retail, automotive, food and beverage and manufacturing industries will all see future growth thanks to AGV- and AMR-driven efficiencies. But countless other industries will also benefit and grow with the increase in AGV/AMR adoption we’re witnessing.

Healthcare and pharmaceuticals. Aerospace. Trucking and logistics. Chemicals. Printing and paper. Textiles. Plastics. These industries represent just a few of many that have aggressively increased their adoption of AGV/AMR technology. And as adoption increases, so does industry growth. Driving that adoption will be AGVs like FRED and FREDDiE. These two robots have all-but eliminated the barrier to entry for automation. They’re incredibly affordable and productive. They can be set up or reconfigured in under two hours. And they deliver near-instant business results with the quickest ROIs of any AGV/AMR on the market. If you operate a warehouse or move materials in a factory, you can no longer afford not to automate. And FRED and FREDDiE finally make automation affordable.

Questions?

If you have questions, we have answers. We love discussing automation, and helping our clients solve their material-movement challenges in new and unexpected ways. Please never hesitate to contact a FRED/FREDDiE Automation specialist at info@fredagv.com.

Sources:

https://www.marketsandmarkets.com/Market-Reports/automated-guided-vehicle-market-27462395.html

https://www.grandviewresearch.com/industry-analysis/automated-guided-vehicle-agv-market

https://www.fortunebusinessinsights.com/automated-guided-vehicle-agv-market-101966

https://www.abelwomack.com/study-global-agv-market-to-nearly-double-by-2024/

https://www.businessinsider.com/amazon-has-huge-savings-potential-from-installing-kiva-robots-2014-12