Pressures are on the rise from all directions for operations and facilities managers in warehousing, logistics, manufacturing, and distribution facilities.

Consumers demand lightning-fast order fulfillment and shipping. Labor shortages and high employee turnover often leave positions unfilled for long periods, slowing down production and making work less enjoyable, setting up companies for more churn. The specter of supply chain disruption means there’s no wiggle room in project scheduling—and in these competitive industries, customers have options.

The tensions have many managers getting serious about automation as part of their modernization efforts. But a revamp of workflows and facilities to accommodate conveyors or robotics can be daunting, disruptive, and costly.

Automated guided vehicles (AGVs) might be just the right point of entry for ops managers looking for an accessible first step in a modernization plan. Their focused capabilities and budget-friendly options make for a simple, low-risk way to try automation before going all-in.

Let’s take a look at what an AGV is (and isn’t), how AGVs work, what tasks they can perform, and how they compare with other automation options for warehousing and manufacturing.

What is an AGV?

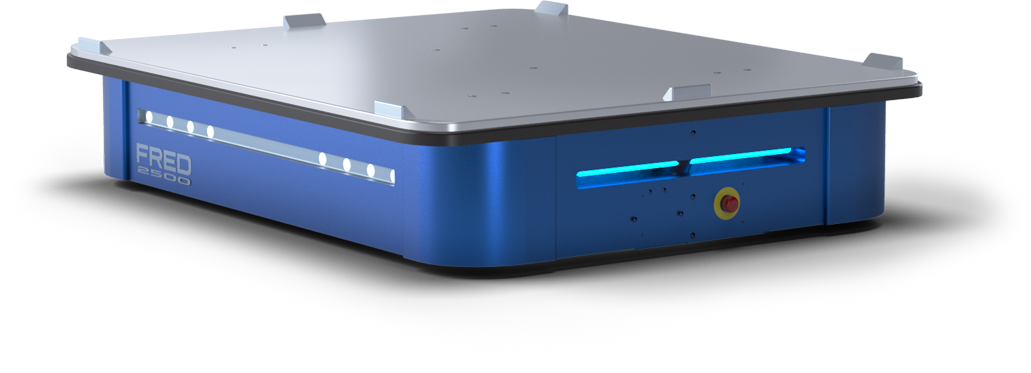

AGVs are self-driving material transporters that follow predefined routes through industrial environments. An AGV’s path is marked by magnetic tape or visual cues, and the AGV’s sensors and collision avoidance system keep it moving safely along the marked route.

AGVs offer safe navigation without human guidance. Integrating one or more into work processes and production lines—especially tasks that create motion waste or transportation waste—allows facilities to cost-effectively pilot test no-frills automation before committing to full implementation.

Unlike more complicated automation tech or conveyor systems, AGVs deliver focused, targeted material transport capability without major workflow or facility changes. Their straightforward integration and operation make AGVs ideal for a facilities’ and employees’ first introductions to automation. And if you opt for an AGV that doesn’t require WiFi network access, you don’t necessarily need IT involvement to move forward.

Comparing AGVs vs. Traditional Forklifts or Tuggers

Unlike fork trucks, dollies, tuggers or carts that require drivers or people to steer, pull, or push when transporting materials, AGVs are fully automated and self-driving. They follow the path, stop to avoid obstacles, and resume motion after objects or people are no longer in their path. This allows them to repeatedly transport loads along an optimized path in a facility.

Some advantages to AGVs over manual material handling include:

Safety improvements—By eliminating human drivers in potentially hazardous industrial environments, AGVs can help reduce forklift-related accidents. Optimized paths for material transport can even allow facilities to designate forklift-free zones without overhauling workflows. AGVs can move the really heavy loads that put workers at risk of injury. And obstacle avoidance technologies, flashing lights, and adjustable alarms help keep workers safe, even in busy, noisy environments.

Efficiency increases—AGVs can operate 24/7/365 with minimal downtime, swappable batteries, and simple maintenance. That supports increased throughput, less likelihood of product damage from improper handling, and a fast path to ROI.

Lower labor costs—A tight labor market doesn't just make it hard to find workers; it adds to the cost of finding, hiring, and retaining them. With an AGV handling dunnage or other basic raw material transport tasks, employees can contribute greater value on the job.

Scalability—It’s easy to scale from one AGV to a fleet to meet increased production demands.

Flexibility—AGVs can come in compact formats that fit safely through spaces where forklifts might not. And it’s easy to revise the route if a warehouse layout or manufacturing workflow changes: just pull up the tape and lay down a fresh path, or reset beacons, depending on your AGV’s navigation method.

What About the Downsides?

It’s true: No single technology solves every challenge.

An AGV isn’t for every job or environment. While AGVs are available in a considerable range of sizes, towing and/or tugging capacities, and even specialized configurations for jobs like stretch wrapping pallets, an AGV does just exactly what it does, and that’s moving stuff. Simply, reliably, all day, every day.

So an AGV’s the best choice for repetitive tasks. Especially jobs that add thousands of steps to employees’ workdays. So what are their limitations?

- Typically, AGVs follow only just path at a time, unless you move the magnetic tape or visual beacons

- A pallet jack may come at a lower price—as long as you don’t add the cost of labor to steer and operate it

- A straightforward, basic AGV is a mover. It doesn’t load or unload

- Different types of AGVs can be configured to meet various needs

- If you need to change your floorplan, plan on revising your AGV path guidance

How Do I Know If an AGV is My Best Automation Option?

Evaluating a facility's specific needs and operations will determine whether AGV or AMR technology is more suitable. Their fixed infrastructure is the trade-off for high productivity, precision, and minimal disruption.

An automation expert can walk you through an evaluation, paying attention to route distances and widths, gates and doors, pitch and condition of floor surfaces, cleanliness, and other details. They can also help you review workflows to choose the best candidate for simple automation.

You can get an AGV up and running in just a couple of hours. And if you’re not ready to commit, renting and leasing options make it easy to track and measure productivity and get an accurate projection of time to ROI. (Pro tip: The more shifts you run, the faster your AGV pays for itself.)

The bottom line: Today’s AGVs are not olden-days automation, and it’s worth learning more about this super-simple way to streamline repetitive tasks and keep work moving. Discover for yourself how new capabilities and breakthroughs in design and tech make AGVs a trusted option in advanced manufacturing and warehousing operations. We’ve debunked 10 common myths about AGVs.