Economic downturns, while challenging to predict, are at least relatively consistent in their frequency. Businesses have learned to prepare and adapt, running leaner and cutting budgets wherever possible. This downturn, though—now coined The Great Lockdown—is a black swan no business could have prepared for. Budgets must still be cut. But to survive, businesses must still invest in productivity.

For manufacturing facilities and warehouses, an investment in productivity typically means an investment in new equipment or employees. But as these companies scrutinize their balance sheets, many will ask if now is the right time for this type of investment. The answer will fall squarely on ROI. The returns on any investment will need to be as fast as they are predictable.

These two qualities of an investment’s return—speed and predictability—can be hard to forecast. But some investments make for an easier ROI forecast than others.

The Cost of a Global Supply Chain

It’s fair to say we can only be certain of two things: more uncertainty and more economic hardship.

“…the peak of the impact of Covid-19 on global supply chains will occur in mid-March, forcing thousands of companies to throttle down or temporarily shut assembly and manufacturing plants…,” claims the Harvard Business Review. “The most vulnerable companies are those which rely heavily or solely on factories in China for parts and materials.”

But even if your business doesn’t rely on China for materials, that means little in today’s global economy. All businesses are now so interdependent, the effects of an economic meltdown ripple throughout every industry. When tourism and travel grind to a halt, it’s not just airlines and hotels that hurt. Every business that supports them hurts, too, along with the businesses supporting those businesses (and so on).

AGVs: Quick & Predictable ROIs

If you’ve ever investigated AGVs for your facility , you’ve undoubtedly encountered the promise of a quick ROI. Virtually every AGV manufacturer claims their technology will deliver blazingly quick returns. But what does a quick ROI really mean?

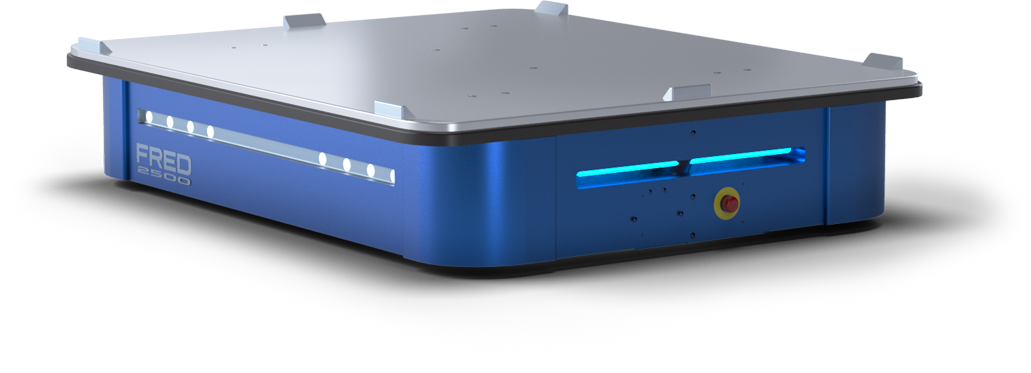

All it takes is a short analysis to find out. ASI manufactures two AGVs, FRED and FREDDiE. So, we’ll use the more expensive of the two, FRED, as our example. And for comparison, we’ll use a common alternative to FRED: a worker moving material with a forklift. To ensure a fair-minded comparison, we’ll use the most conservative figures available. We’ll also exclude highly variable “soft” expenses like the costs of recruiting, hiring, onboarding and training an employee.

Forklift Costs

FRED, ASI’s heavy duty AGV, can carry up to 2,500 lb. and tow up to 5,000 lb. As of this writing, you can pick up a used 2007 Toyota 8FGC20 4,000 lb. forklift on eBay for $8,950 plus shipping. We’ve chosen this used model because it’s one of the least expensive available that comes close to matching FRED’s material-movement capabilities. And, while not quite as hard-wearing as FRED, Toyota’s machines are regarded as some of the market’s longest lasting.

Most estimates on the cost of year-one forklift maintenance come to around $700. And under typical circumstances, the forklift would operate for about 1,500–2,000 hours per year. To keep our calculations conservative, let’s assume this 2007 model is as good as new (hence the low maintenance costs) and would have no trouble hitting 2,000 hours per year. This assumption will also help simplify our calculation.

A Toyota forklift could, if expertly maintained, last 20,000 hours. That would give it a useful life of 10 years. Now, let’s see where these very conservative figures land. To be safe, we’ll assume free shipping to your facility (if for no other reason than FRED ships free).

- Forklift: $8,950

- Shipping: Varies ($0)

- Year-one Maintenance: $700

- Total: $9,650

- Lifespan: 10 years

- Cost per Year: $965

To recap, a used 2007 Toyota forklift operating 2,000 hours per year for 10 years, with free shipping and only $700 in annual maintenance and servicing costs $965 per year to operate. But without an operator, it’s earning a negative return for the business that invested in it. Let’s now add labor to the equation.

Factoring in Labor

To be clear, the purpose of an AGV like FRED or FREDDie is not to replace an employee or take jobs from an existing workforce. Its purpose is to augment an existing workforce and add efficiencies that help them work more safely and productively.

Given the current economic and labor climate, we’ll avoid including the “soft” costs of recruiting, hiring, onboarding and training a new worker. For worker wages, we’ll pull recent data from the U.S. Bureau of Labor Statistics (BLS).

In December 2019, the average “Production and Nonsupervisory” worker in the “Warehousing and Storage” subsector earned $18.42 per hour in base pay. That worker hit an average 42.5 hours per week*.

But that worker’s employer paid more than $18.42 per hour. Payroll taxes. Benefits. Workers’ compensation insurance. These additional costs add up. And while they vary from state to state, a low estimate would be 20% more than base hourly pay. To keep these calculations conservative and orderly, though, let’s bring the worker’s base pay down to $15 per hour. Adding 20% to that for payroll, benefits and workers’ comp brings us to an even $18 per hour.

Let’s also assume this worker doesn’t get paid vacation. They’re working 50 paid weeks per year.

- Base Pay: $15/hour

- Payroll Taxes, Benefits & Workers Comp: $3/hour

- Base + Taxes, Benefits & Workers Comp: $18/hour

- Hours Worked per Week: 42.5

- Paid Weeks per Year: 50

- Cost per Year: $38,250

To recap, a material-moving employee working 42.5 hours per week at $15 per hour with no paid vacation costs $38,250 annually. Once we add the previously calculated forklift costs to the equation, we arrive at an annual business expenditure approaching $40,000.

AGV Costs

AGVs vary widely in price. But we’ll continue using FRED, our heavy-duty AGV, as our example. FRED costs $35,000. Including shipping. At this point, we have an answer to the question posed by this article. AGV’s can achieve an ROI within one year.

In fact, FRED would have saved its purchaser nearly $4,000 in that first year. And that’s assuming it only works 42.5 hours per week for 50 weeks per year. But FRED can work 24/7/365, only taking an occasional break to recharge its batteries.

A typical scenario would have an AGV working two eight-hour shifts every day. That workload would be equivalent to roughly 2.75 forklifts and operators that cost an employer $107,112 per year. Under this scenario, FRED still costs $35,000, saving its purchaser $72,112.

The right AGV achieves full ROI in about 4 months. Conservatively.

After month four, the AGV delivers nothing but profit. But what about installation costs? Maintenance?

Some AGVs are more expensive to install and maintain than others. They may require costly software maintenance agreements and programming, along with strong WiFi, bluetooth or GPS signals throughout your facility. Essentially, they need ongoing IT.

But there are AGVs on the market designed to require none of the above. The AGVs from ASI, FRED and FREDDiE, are two of them. Because they follow a magnetic tape path, they don’t require software or any sort of connectivity, which eliminates IT costs. As far as installation costs, there are none (other than the two hours of your time needed to set up its route).

AGVs Achieve More than Just Quick & Predictable ROIs

We’ve established that the right AGV can achieve ROI in well under a year. But it delivers other efficiencies too. That worker who’d otherwise be driving the forklift can now be redeployed to more productive tasks that demand more skill than material movement. A move like that is equivalent to hiring a new employee, minus the expense. The freed-up worker is essentially a free worker.

If your facility allows for it, you could even eliminate the need for forklifts entirely. That would produce a number of benefits, including the removal of forklift-free areas to expand your productive footprint. It would be like gaining free real estate.

The COVID-19 pandemic has also driven increased demand for AGVs as measures to enhance worker safety and productivity. In early April, we published an article called Fighting a Global Pandemic with Automation. This article highlights five examples demonstrating how AGVs can:

- Keep your skilled labor where they offer the most value;

- Maintain operations even when your workforce becomes ill;

- Promote a safer work environment;

- Make staggered shifts more productive; and

- Allow for more employees to work remotely.

Each example goes into more detail, which you can read via the link above. The examples further illustrate how automation can protect your workforce, productivity and ultimately your business.

A Lasting Competitive Advantage

The quick and predictable nature of an AGVs ROI extends well beyond the current pandemic-induced financial crisis. The economy will recover. And businesses that made the wise decision to invest in AGVs are likely to come out on top. They’ll have saved significant money and increased productivity during a time when doing both was crucially important. For many businesses, this push toward more efficiency may even be what kept them afloat.

Just as important, the savings could have allowed a business to retain more of its workforce. When the worst of this pandemic ends, employee retention will be a huge competitive advantage. As hiring once again resumes, they’ll not be competing for labor as the market tightens. They’ll have a workforce fully accustomed to working alongside AGVs. And they’ll know where next to invest in automation. For most warehouses and manufacturers, AGVs are the cornerstone of end-of-line (EOL) automation. The more EOL processes can be automated, the more efficient and productive a facility becomes.

It may seem counterintuitive, but now—in the midst of a catastrophic financial crisis—is probably the best time to invest in automation. All it takes is a quick look at the numbers to see why. Under the scenario we outlined, just one AGV like FRED can save a business nearly $75,000 during its first year in operation. And that calculation factors in the AGV’s cost. After year one, the annual savings climb to well over $100,000.

Sustainable Productivity

Both the societal and economic impacts of COVID-19 have been devastating. Businesses have shuttered—many permanently. More still will be forced to. But history has taught us important lessons about the ways businesses react to threatening economic climates. It will be those that best optimized their operations and productivity today that are positioned to benefit the most during the inevitable economic recovery. Because they’ll have sought every possible efficiency, they’ll have realized the powerful benefits of affordable automation. Safety. Simplicity. Cost savings. And most importantly, sustainable productivity, even during the worst of times.

Ask Us Anything

If you have questions, we have answers. We love discussing automation, and helping our clients solve their material-movement challenges in new and unexpected ways. Please never hesitate to contact a FRED Automation specialist at info@fredagv.com.